- Our project managers with fluent English skill have rich experience on project management, we designate a project engineer to follow up with the customer’s projects, so simple communication only.

- The project managers keep a close eye to tooling schedule from the customer’s perspective, to make sure of the quality and delivery time. And weekly report with requirements will be sent to the customer.

- The project managers are directly reported to the General Manager to guarantee their instruction are followed by the factory.

Work Flow

Part feasibility analysis (with customer)

- Cost re-evaluation

- Lead time pre-check

Design Preparation

- Get 3D/2D drawing & customer Tool Standard (refer to picture Customer Tool Standard Example), Specification (refer to Specifications example)

- Design meeting (project manager, R&D, toolmaker, processing engineer)

- Mold flow (if necessary) ( Mold flow video on Youtube, Mold flow analysis in PDF.

- Layout Solution

Tool Design

- Tool design start and self-check according to GA checklist

- Design review meeting (3D tool design review, manufacturing workmanship review)

- Tool design to customer for approval

- Tool design adjust according to customer comments

- Repeat this until customer final approval

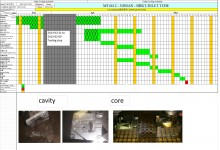

Schedule

Send final detailed daily schedule to customer.

Procedure Control

- Weekly report to customer by photos, E-mails, Skype meetings

- Project manager daily follow up according to schedule

Preparation for Trial

Project manager gets information for samples quantity, color, raw material ready f for processing engineer.

Project manager gets information for samples quantity, color, raw material ready f for processing engineer.

After T1

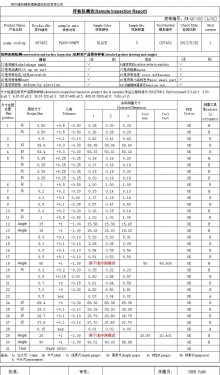

- ISIR (Initial Sample Inspection Report) for 5 samples per cavity

- Samples to customer

- PFU (Problem Follow Up) which contents photos of detailed problems and suggested solutions

- Pre-delivery tool inspection according to check list

Modification & Correction

- Dimension correction upon ISIR and customer’s feedback upon samples

- Evaluate with customer for modifications and supply new trial time

- Repeat until customer final approval on samples

Tool Inspection

- Final self tool inspection

- Some customers come over for tool inspection

- Capability study by running small batch production

Shipping

- Arrange either door to door or door to port service for tool delivery

- Send delivery information (ETD, ETA, Vessel name etc) to customer

- Check with customers for their trials in house about the tool performance in 10days upon tool arriving.

- Final conclusion meeting for summary.